A Common Beer Tank Lining Issue and How to Mitigate It

Article by Nathan Hartgraves

It has commonly been stated that brewing great beer is a ‘science.’

Even though beer makers have been perfecting this glorious beverage for over 5,000 years and have been testing the limits of that science, there are certain “laws” that should never be violated. Along with the necessity of the Great Four Ingredients, there are other aspects of beer making that play a pivotal role in the delivery of brewing success. One of these is storage. And, for more than 100 years, Enerfab has been ensuring that the internal surfaces of beer storage vessels all over the world are lined with the best treatment possible.

Unfortunately, whether a storage vessel was lined with brewer’s pitch in the days of yore or with the more advanced 100% solids-epoxy systems of today, there are times when a variety of issues can present themselves. While there are several complications that may arise, this article focuses on one phenomenon, which 90% or more of beer makers will likely observe at some point in their tenures: osmotic blistering.

What Is Osmotic Blistering?

In the tank lining industry, osmotic blistering is one of the most common lining defects that coating and lining inspectors observe. When a beer maker sees blisters in their tank lining, the first response may be to assume that someone specified and applied the wrong tank lining. However, inspectors see that even with the correct tank lining, osmotic blistering can occur.

In the tank lining industry, osmotic blistering is one of the most common lining defects that coating and lining inspectors observe. When a beer maker sees blisters in their tank lining, the first response may be to assume that someone specified and applied the wrong tank lining. However, inspectors see that even with the correct tank lining, osmotic blistering can occur.

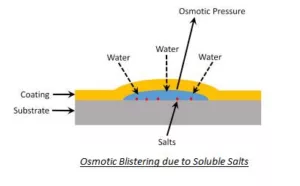

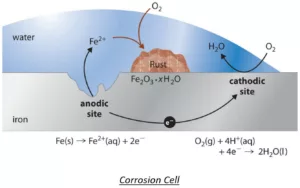

So, what is osmotic blistering, and what does it look like? Osmotic blistering happens when two substances attempt to reach balance or equilibrium through a semi-permeable lining film. This blistering manifests itself in a domed projection in the lining film where the film has broken free of its mechanical bond to the underlying substrate. Blisters can be circular or present themselves in irregular shapes depending on the cause. This can have the appearance of chickenpox all over the lining, so the lining looks sick! When ruptured, water, beer, or both will be present inside the blister. Along with the liquid contents, corrosion of the steel in the form of rust can develop. Within the brewing industry, the three most common causes of osmotic blistering are the presence of soluble salts, thermal gradients, or both.

Osmotic Blistering from Soluble Salts

Chlorides, sulfates, and nitrates are common soluble salts, which are known to cause osmotic blistering. When these salts are left on the substrate and allowed to be lined over, the salts draw moisture through the semi-permeable lining film to reach balance. Once this occurs, a corrosion cell is formed. As the corrosion cell develops and the volume of solution increases at the substrate/ lining interface, osmotic pressure creates a void between the lining and the substrate, resulting in the blister.

Sadly, this problem, while easily addressed during the surface preparation stage of the lining process, is often overlooked until after the damage is done. Testing for the presence of soluble salts as well as washing the steel substrate with a chloride remover can go a long way in preventing the issue before it starts.

Osmotic Blistering from Thermal Gradient

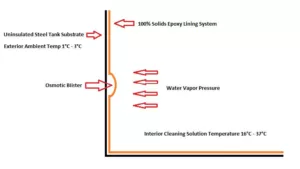

Just as in the case of osmotic blistering from soluble salts, blistering from thermal gradients is related to the natural propensity for two areas to reach equilibrium. In this case, when an uninsulated beer tank is in a cold cellar service, the tank wall reaches a surface temperature of the surrounding ambient cellar temperature. Generally, this is between 1°C – 3°C. The beer is stored in the tanks and reaches the cellar temperature during its time there. So far, so good.

However, once the tank is emptied and cleaning begins, issues can arise. It is not uncommon for breweries to clean their tanks with a caustic and warm or hot water solution between 16°C – 37°C to remove solids prior to sterilization. The introduction of a higher-temperature solution to the interior tank wall and lining creates a thermal gradient. This is also known as “Cold Wall Effect.” When this happens, the water-vapor pressure on the warmer side of the lining film is stronger than the water vapor pressure on the colder, tank-wall side. This pressure causes water vapor to permeate through the lining film to the substrate/lining film interface. The increase in volume then causes outward osmotic pressure away from the substrate, breaking the lining film’s mechanical bond. If soluble salts are present, this action accelerates the blistering.

When cleaning beer tanks in cold cellars, it is recommended that there be no more than a 10% difference in the ambient, tank-wall temperature and the cleaning solution. Some breweries may be concerned that cooler cleaning solutions will not be effective in the removal of soils but increasing the caustic by 2–3% can make up for this change in temperature. It is also worth noting that most lining films designed for this type of service are not detrimentally affected by the increase in caustic percentage.

The Bottom Line

While osmotic blistering is only one of several lining issues that the brewing industry may encounter, it can be the cause of some serious headaches. Once blisters rupture, there is room for moisture migration behind the lining film and if breweries do not correct it immediately, the rupture and accompanying moisture migration can lead to widespread lining failure.

Of course, the best way to deal with this issue is to address it before the execution of a tank re-lining project. The cost of being proactive will save breweries more in the long run, not only in lining repair costs but in brewery downtime and product quality as well.

Cheers!!

—

Want to learn more?

Visit enerfab.com/coatings-linings to see more about our Protective Coatings & Linings division.

About Enerfab

Founded in 1901, Enerfab has a rich history, as an industry leader in providing fabrication, construction, and maintenance services within the utility, chemical, refinery, food & beverage, and heavy industrial markets. Headquartered in Cincinnati, Ohio, Enerfab is one of the fastest-growing privately held companies in the area, employing approximately 2,000 people and operating four regions – Ohio Valley, Great Lakes, Midwest, and Eastern.

About the Author

Nathan Hartgraves is the Director of Protective Coatings & Linings at Enerfab, Inc. headquartered in Cincinnati, Ohio. Nathan is a Coatings & Linings expert with 20 years of experience. He is a NACE Certified Coating Inspector as well as a NACE Instructor.

References

Laurence W. McKeen, in Fluorinated Coatings and Finishes Handbook (Second Edition, 2016

Munger, Charles G., Corrosion Prevention by Protective Coatings (Third Edition, NACE International 2014

Ed Petrie, EMP Solutions, Osmotic Blisters in Coatings and Adhesives, 12 October 2011

Jim Machen, KTA University, Common Causes of Blistering and Bubbling in Industrial Coatings, 12 July 2016