Technology & Innovation

As our customers and markets grow, we strive to stay a step ahead by introducing new technology, innovation, and unique ways of working that create safer, more efficient projects, job sites, and shops. The technologies and work processes below just scratch the surface of the innovative approach we take to your projects.

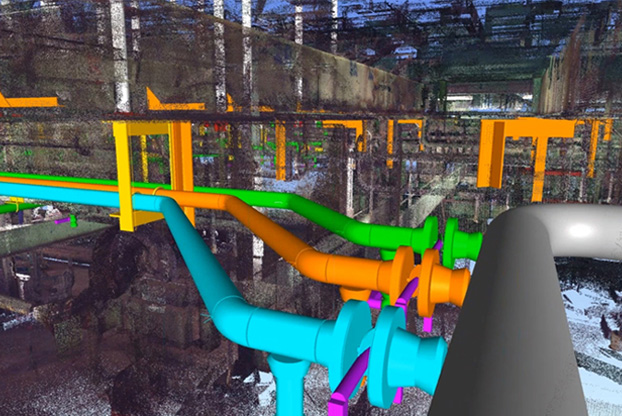

3D Laser Scanning

New 3D Laser Scanning capabilities quickly capture over 3 million data points on facility structures and systems to produce near-perfect 3D models.

Scanning

Digital scanning shortens shutdowns and mitigates safety risk while capturing data much quicker than traditional measuring processes.

Engineering & Design

Once captured, scans enable accurate design reviews before construction and optimize constructability of even the most complex projects.

Project Control

Throughout the life of the project, 3D scans aid to verify equipment installation, track project status, and ultimately close the communication loop with more consistent data.

4D Project Scheduling

Enerfab’s 4D Project Scheduling gives customers a look into the future by pairing the 3D models with the comprehensive project plan to visualize the schedule over time in video form. Project teams and plant decision makers can now better understand the complexities of the project, ultimately mitigating safety risks and minimizing change orders associated with critical path challenges.

eTrack Dashboard

The Enerfab eTrack Dashboard offers our customers a real-time look at how and where money is being spent during the life of their project. This customizable, interactive dashboard provides unparalleled insight into projects costs based on a wide range of criteria including:

- Cost breakouts

- Actual and open-billed invoices

- Nonlabor costs

- Real-time labor costs

- Hours and apprentice hours by craft

- Billing dollars by month and by craft

- Budget vs. actual costs

Modular Construction

Process modules, piping skids, and prefabricated pipe racks move work from the field to the shop to manage a tight labor market, meet demanding schedules, mitigate safety risk, and help your budget.

Modules are pre-piped, pre-wired, and made ready for quick installation before being shipped to the job site. And when the modules are ready to leave our shops, we have turnkey field solutions to take it from there.

Drone Inspection

The safety of our workers and the quality of your equipment are at the top of our priority list. Critical inspection of your equipment calls for a lot of additional resources and often creates significant safety hazards.

Drone inspection offers an alternative approach to high-risk inspection procedures. Utilizing a high-definition camera, the drone operator can capture video and photos of critical welds and other areas inside the equipment to determine maintenance requirements without any employees having to enter the unit.

In the demo video below, this particular equipment inspection would have required line break, piping removal, and scaffolding. This alternative called for no additional equipment and removed the safety hazards for employees, ultimately saving the customer tens of thousands of dollars, in addition to minimizing downtime.

Rapid Response

In rapid response, production begins on day one. Planning, engineering, and execution coincide to meet your tight turnaround window. And your partners at Enerfab work alongside you every step of the way to ensure that safety and quality are never sacrificed despite the accelerated timeline.