Thomas Hill Energy Center (THEC) had a problem: Its current ash handling system had become a maintenance disaster. The system — common in most power plants and consisting of ceramic-lined pipe and fittings that moved a highly-abrasive ash and water slurry — was holding up well except at changes in direction, where blockages were common.

Workers would frequently bang on the pipes to clear those blockages, causing the brittle ceramic lining to fracture and break down quickly. The broken lining and damaged pipes led to increased outages, costing the plant time and money.

Who Is … ?

Enerpipe is the pipe fabrication division of Enerfab. Headquartered in New London, Wisconsin, Enerpipe fabricates, ships, and installs pipe nationwide. Its purpose-built shop and investments in pipe fabrication technology and labor make Enerpipe a premium pipe supplier within many industries — including power generation, refining, chemical, and food & beverage.

Iracore International LLC designs and manufactures custom wear materials to solve abrasion and corrosion issues. Across the markets it serves, its clients get more from their assets, experiencing better reliability and significantly increasing their equipment lifecycle. The 3+ million feet of pipe installed with Iracore linings, custom rubber projects, and hundreds of thousands of molded and cast parts have been proven worldwide. |

An Opportunity for Partnership

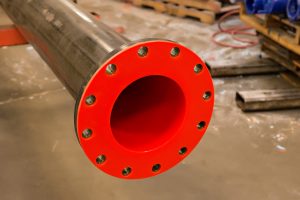

Enerpipe and Iracore saw the THEC project as an opportunity to showcase both companies’ unique capabilities and offer THEC a solution new to their industry that had proven successful in others.

An already trusted pipe fabricator for Associated Electric Cooperative Incorporated (AECI), owner and operator of the Thomas Hill facility, Enerpipe approached leadership and offered to install test spools of elbows and straight-run sections that made use of Iracore’s specialty product — polyurethane-lined pipe designed to resist abrasion and stand up to the beating these pipes took regularly.

The test would prove the value of polyurethane-lined pipe by reducing the overall cost of operation in the form of lower maintenance costs compared to the previous ceramic-lined system.

Built for the Long-Term Challenge

Enerpipe installed the test run during a routine outage in 2013. And because handling usually requires high maintenance and inspection, the durability of Iracore’s polyurethane lining was observed closely.

The result: after seven years of continuous use, there was little-to-no visible corrosion. No piece of the system ever required replacement due to lining breakdown — a huge improvement over the previous ceramic lining. In fact, the routine beating of the pipes to clear ash blockages had no effect on the polyurethane-lined pipe whatsoever.

Results that Add Up

While AECI decommissioned the piping system in 2020, plant managers at Thomas Hill remained confident that the lined pipe would have lasted much longer than the seven years it was in operation. Leadership at AECI was so impressed that they wrote a letter of referral, which you can read here.

While AECI decommissioned the piping system in 2020, plant managers at Thomas Hill remained confident that the lined pipe would have lasted much longer than the seven years it was in operation. Leadership at AECI was so impressed that they wrote a letter of referral, which you can read here.

Compared to the rate at which the old system needed parts replaced, the premium for polyurethane-lined pipe was more than made up for in maintenance savings. The result was a very successful test for AECI, and confidence to use the system on a larger scale in the future.

Ready to learn more?

Let’s talk about how lined piping can help you reduce maintenance costs and increase profitability. Fill out the form below, and a member of our team will be in touch right away.