History

125 Years of Doing the Hard Work

Since our founding in 1901, Enerfab’s strong work culture, diversity of operations, and quality of employees have made us an industry leader. We continue to serve our customers with safety, quality, and innovation. Scroll through the timeline below to better understand our rich history.

The Founding

Peter Allison Bishopric signed the Articles of Incorporation for The British-American Sealing Wax Company. The enterprise was formed for “the purpose of fabrication, dealing in, and importing the materials for making sealing wax and lacquers.”

Coming from a long line of enterprising inventors and entrepreneurs, Bishopric took advantage of the pro-business climate of the time to establish a legacy for his three children, Charlotte, Emerson, and Allison, Jr. Bishopric credits his father with teaching him that a business required not only ingenuity, capital, and the ability to withstand some risk, but also needed the talents of a great salesman to ensure its success.

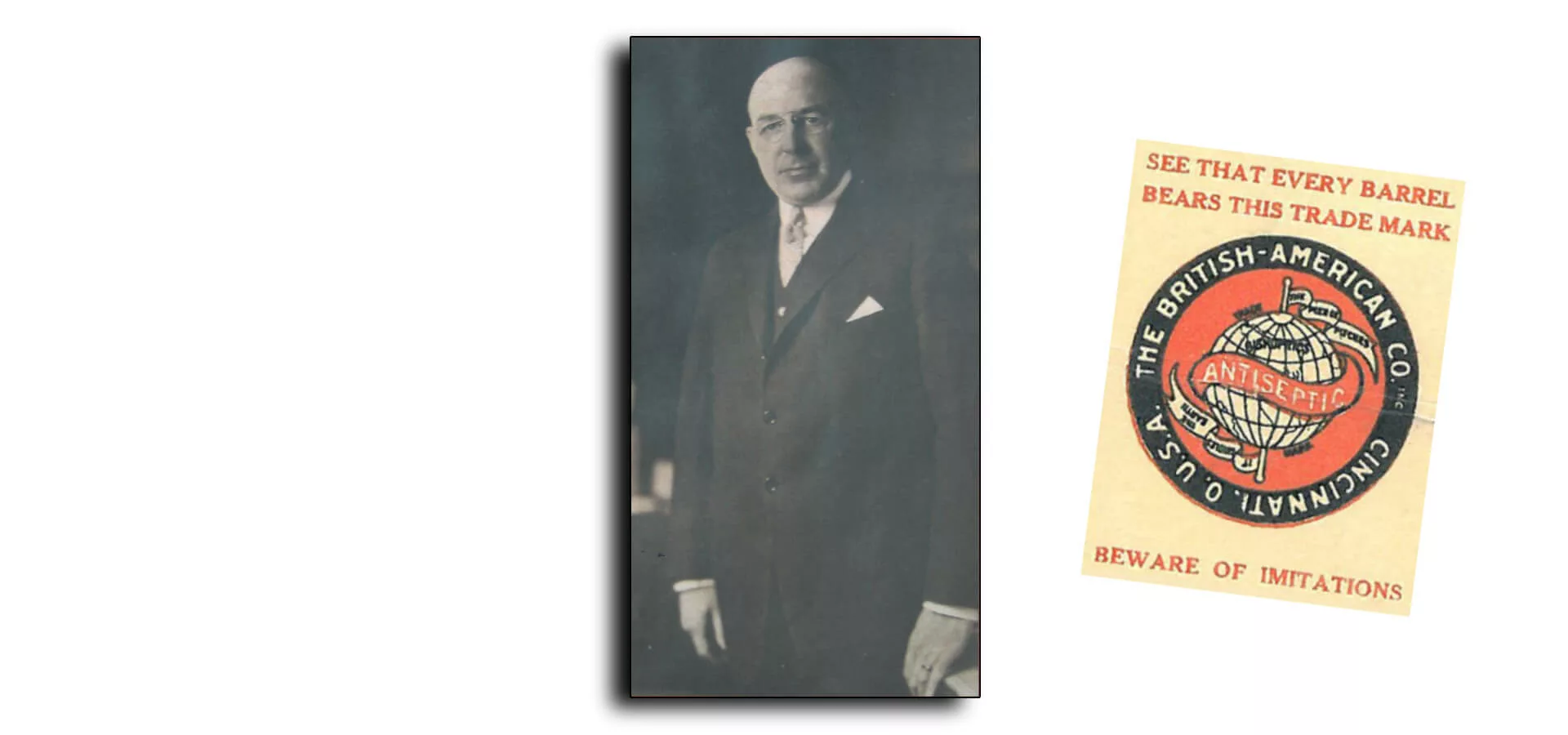

Patent

Allison Bishopric received a patent on his formula for brewer’s pitch and was assigned serial number 14,016 for sanity mastic on this date. The right product in the right place at the right time was the hallmark of the beginnings of the company. By producing and selling brewer’s pitch, used to line the inside of wooden beer barrels, The British-American Sealing Wax Company benefited from its location. At the time, Cincinnati residents consumed more beer per capita than any other city in the nation.

New Name

The British-American Sealing Wax Company changed its name to The Bishopric Products Company. Despite an increasingly vocal movement for beer and liquor reform, the company continued to do well, thanks to its connection to the brewing industry. However, even that was about to change with the onset of Prohibition.

Prohibition

Ohio passed the Ohio Prohibition on Alcohol Amendment (Amendment 2), which prohibited the manufacture and sale of intoxicating liquors as a beverage. The company’s linings division suffered. Additionally, the company’s founder and most creative technical innovator, George F. Bishopric, died of pneumonia during the flu pandemic.

Fabrication

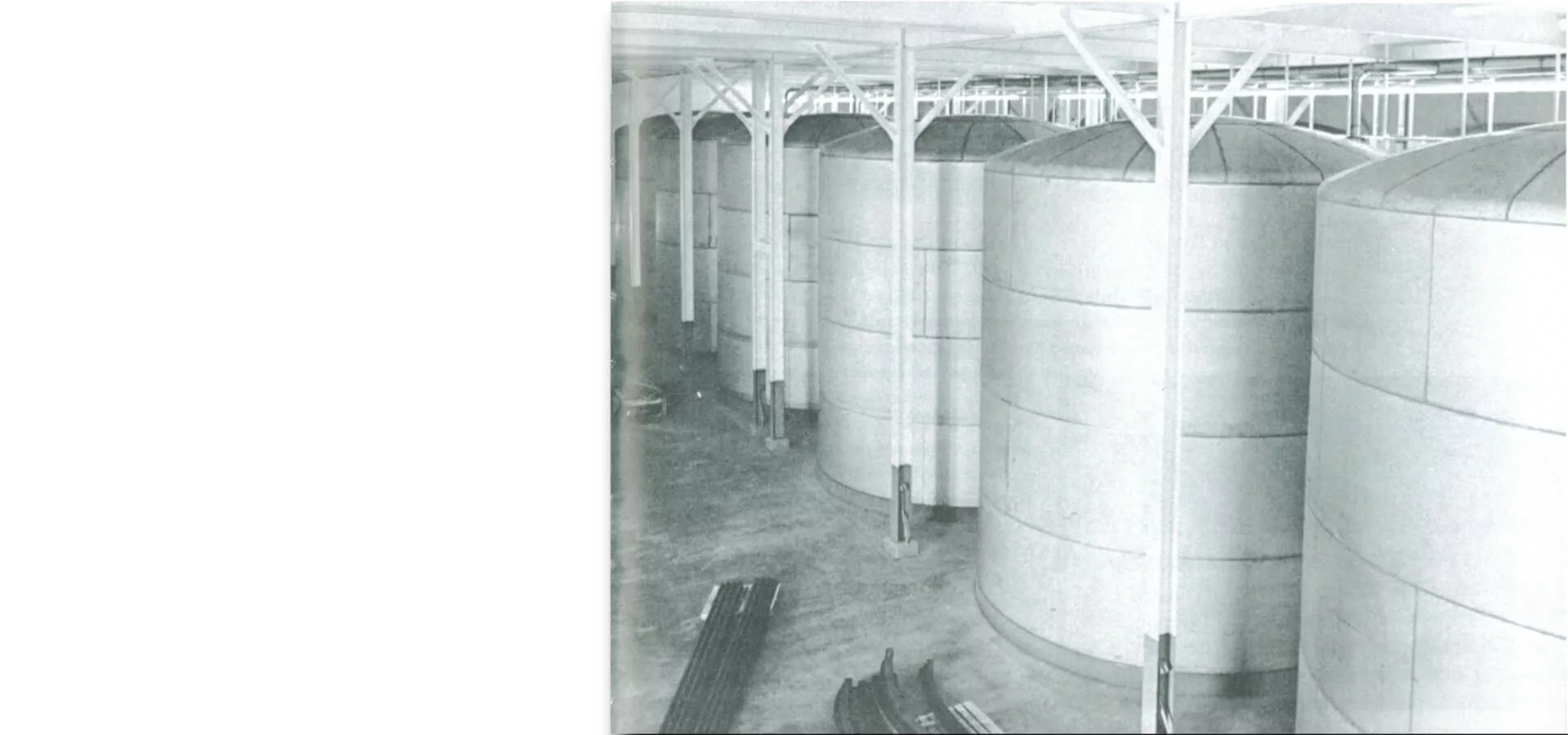

As the Linings Division grew through contracts to re-line existing tanks, orders came in to apply LASTIGLAS™ Munkadur to new tanks that were built by other steel fabricators. Bishopric Products saw an opportunity and began fabricating their tanks, and the Enerfab Fabrication Division was born.

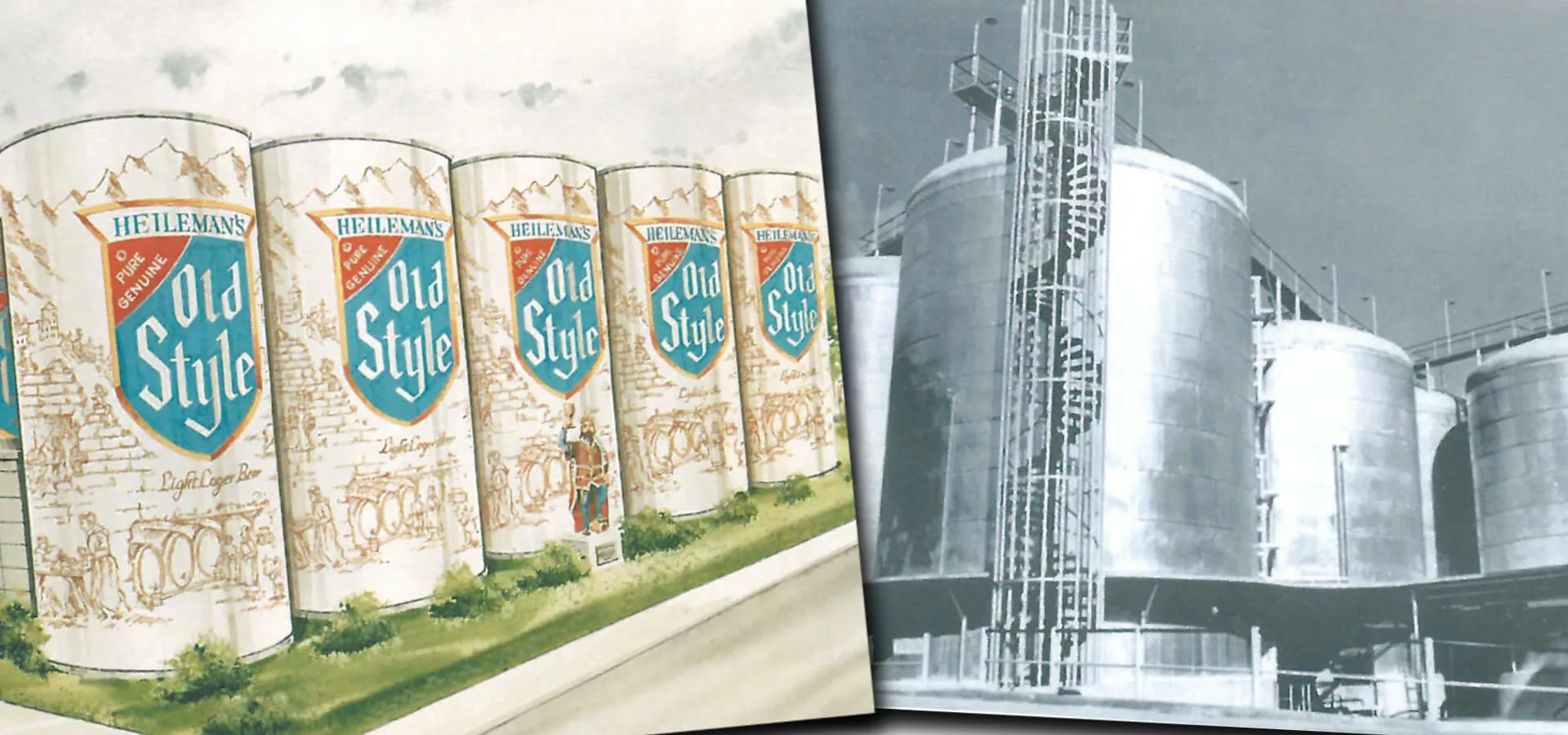

Outdoor Vertical Tanks

Bishopric Products installed the first 4,000-barrel vertical tank for the National Brewing Company in Baltimore, MD. The large vertical tank concept offered the brewers increased capacity and reduced the cost per barrel.

Field Erection

The ability to weld sections into one-piece tanks in the field was a milestone for the company and allowed them to offer a broader range of tank designs to meet customer needs.

First Stainless Contract

Bishopric signed its first major contract for stainless tanks for Schaefer Brewing Company of Brooklyn, NY. This began the company’s long journey toward excellence in the fabrication of stainless and other alloy materials.

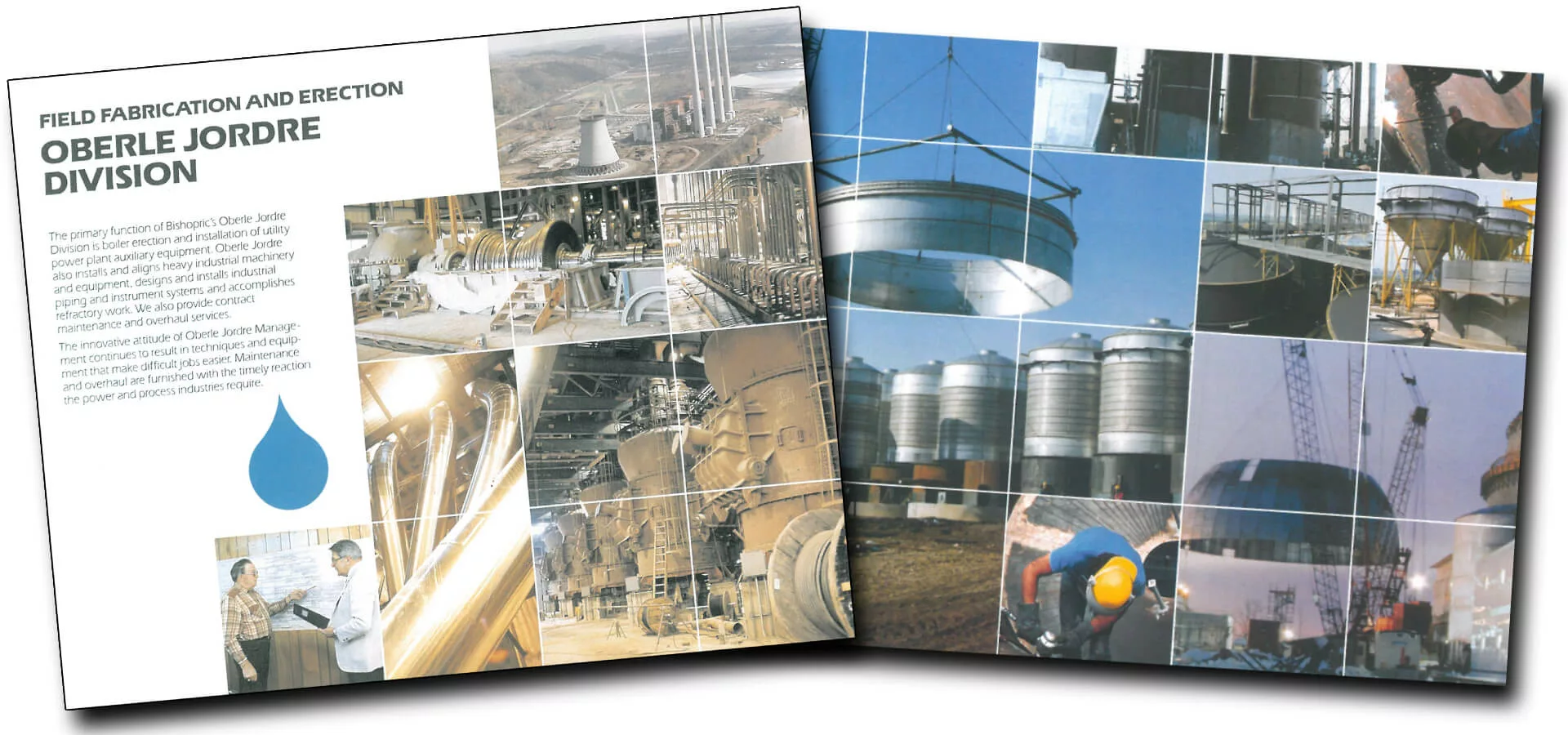

Birth of Power

The Power Division, which is the largest and fastest growing division of Enerfab, was created as the direct result of Bishopric Products’ $500,000 purchase of Oberle Jordre (OJ). Oberle Jordre was primarily responsible for erecting boilers and installing auxiliary equipment for utility power plants.

Enerfab

The company changed its name to Enerfab to identify with emerging opportunities. The name is derived from the debates on “Engineering, Energy, Erection, Fabrication) hence – Enerfab.

Aseptic Storage

Enerfab pioneered the concept of a turnkey storage solution for the citrus industry. This system aseptically stores single-strength orange juice, offering state-of-the-art, economical storage of not-from-concentrate juice, while still preserving its fresh, high-quality characteristics. This storage system encompasses all aspects of Enerfab’s expertise, from site preparation and permitting to training, final start-up, sterilization, and filling. The benefits of aseptic storage are improved product quality, less waste, lower operational costs, and lower maintenance.

Regional Expansion

Enerfab opened its first regional office, located in Bridgeville, PA, to provide industrial construction services, maintenance, and capital project installations to the power industry and general industrial facilities located in Pennsylvania, West Virginia, and Ohio.

Acquisition of Fishbach Power Services

Enerfab finalized the acquisition of Fishbach Power Services, Inc., an industrial boiler maintenance company, which added another maintenance business to Enerfab’s presence in Kansas City/ The KC regional office of Enerfab now provides services to a variety of power, industrial, and other customers within 300 miles.

Enerfab Purchases Brighton Tru-Edge

Enerfab purchased Brighton Tru-Edge, perhaps one of the most pivotal acquisitions, adding cold-formed head fabrication to its capabilities. This allows for better control of schedule and the ability to fabricate pressure vessels and tanks. Brighton Tru-Edge, with its signature Tru-Edge Bevel, is the largest cold-forming head manufacturer in North America today.

Croll-Reynolds Clean Air Partnership

Enerfab teamed up with Croll-Reynolds Clear Air Technologies to develop wet electrostatic precipitator technology with capabilities in the power generation industry. Propelled by the new technology, Enerfab developed an expanding footprint in the AQCS market.

Acquisition of Phillips Getschow

Enerfab acquired Wisconsin-based Phillips Getschow, a mechanical contractor specializing in boiler systems and metal fabrication. The purchase allowed Enerfab to expand in the Upper Midwest and gain capabilities in additional industries, including the paper industry and refineries.

Acquisition of Aycock Marino

Enerfab added Aycock Rigging, now operating as the Harrisburg Regional Office, to the team. This acquisition brought expertise in heavy rigging, structural steel erection, maintenance of power facilities, and prevision installation of power and industrial equipment, further enhancing Enerfab’s ability to meet customer needs.

Acquisition of Hamilton Kettles

Hamilton Kettles became a part of the Enerfab family of companies. Hamilton Kettles is known for its pressure kettles, mixers, and agitators used in pharmaceutical, cosmetic, and food settings. The company offers expertise in ASME code fabrication, sanitary finishes, standard parts, and sanitary designs in 3A, USA, and FDA.

Acquisition of Piping Systems

Enerfab purchased Piping Systems, one of our longtime partners. The company delivers expertise in carbon steel, stainless steel, and nickel alloy pipe fabrication – now known as Enerpipe.

Acquisition of Brown Electric

Brown Electric, located in Dunbar, WV, became a part of Enerfab in 2010, expanding the company’s services to include electrical contracting, maintenance, upgrades, instrumentation and controls, and commissioning to better serve customers. The acquisition now operates as Enerfab Power and Industrial and maintains the West Virginia offices, serving customers throughout the country in the chemical, petrochemical, utility, and natural gas industries.

Acquisition of Foley Company

Enerfab Power and Industrial, Inc., acquired Foley Company, a leader in mechanical contracting and general construction.

Acquisition of TMI Contractors

Enerfab acquired TMI Contractors, based in Mount Vernon, Indiana. TMI Contractors (now TMI Fabricators) is a fabrication and construction company specializing in structural steel fabrication. TMI played an integral part in the overall strategic growth plan and diversified our product offers across the entire company.

The Creation of Enerfab Modular

As the markets tightened and business accelerated, the demand for modularization and prefabrication in projects increased, so we adapted as well.

We launched Enerfab Modular, a new division dedicated solely to fabricating and executing modular projects to handle every aspect of modular construction scopes.